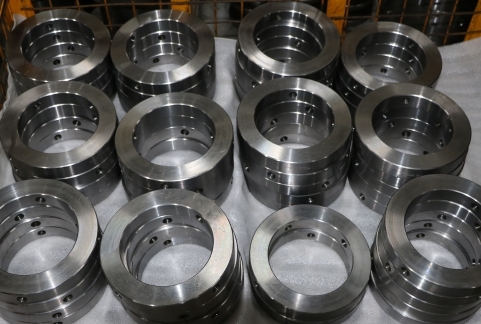

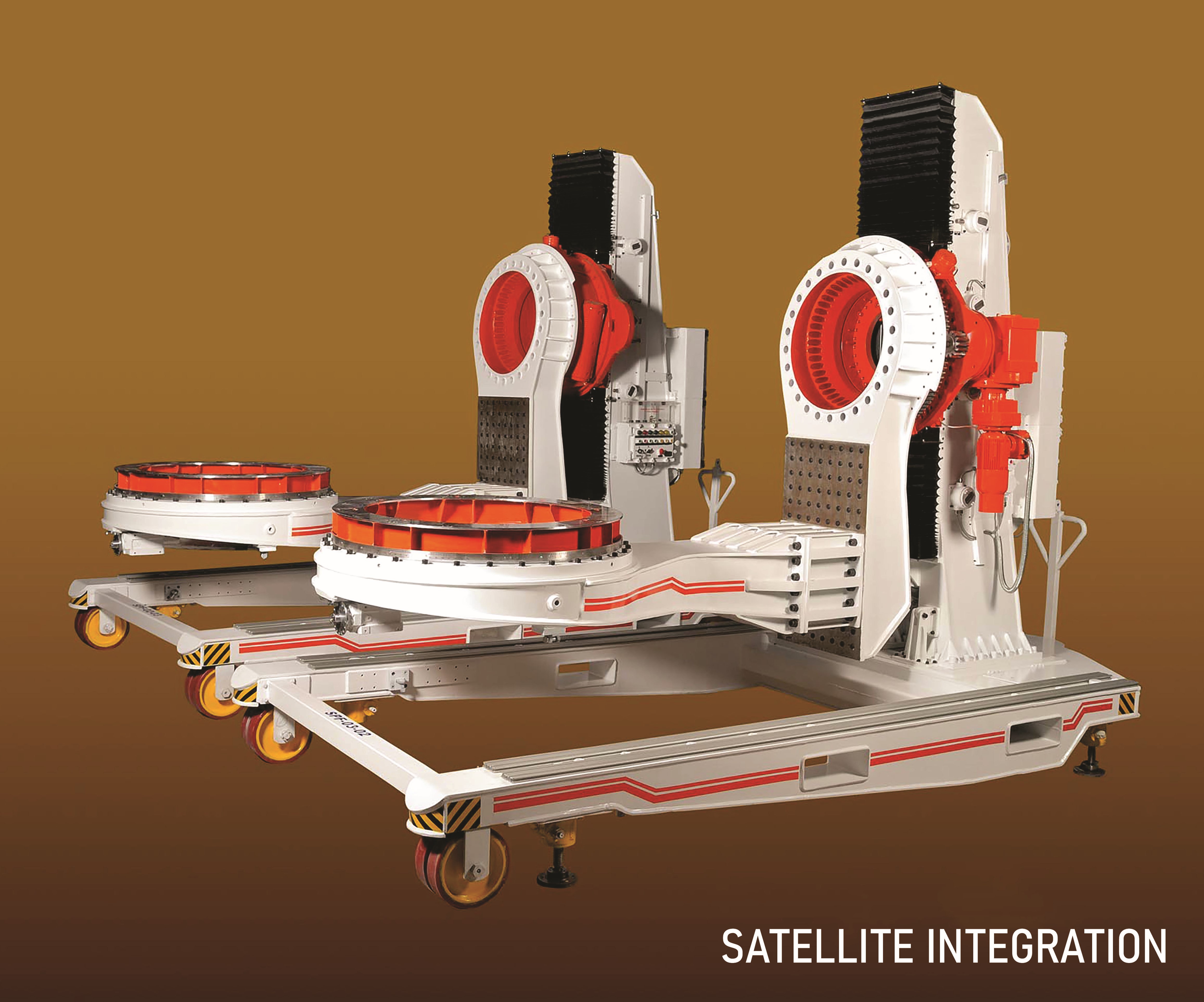

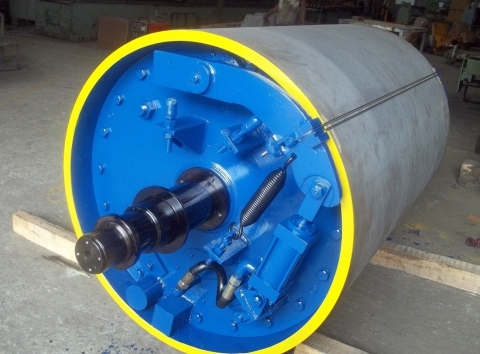

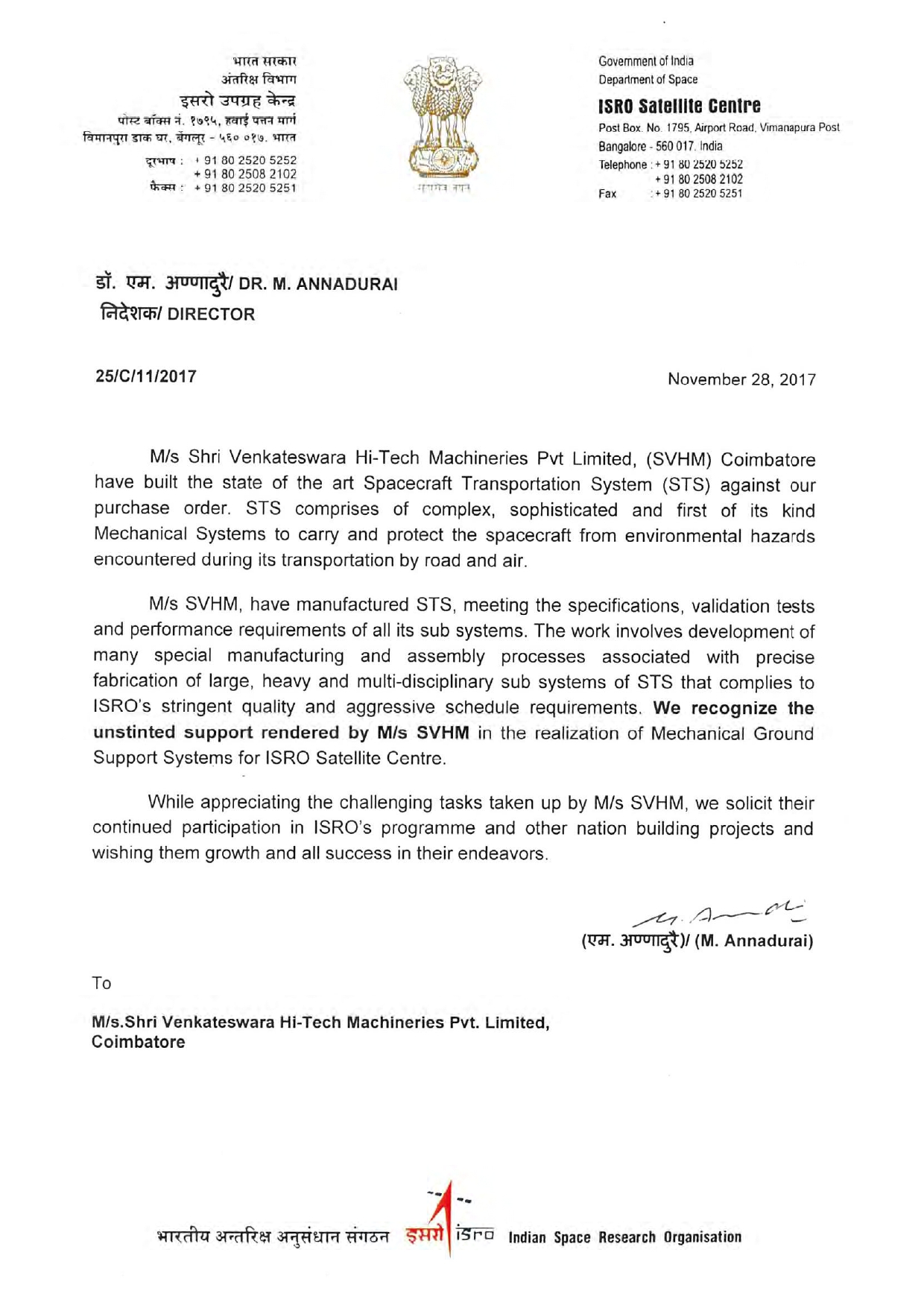

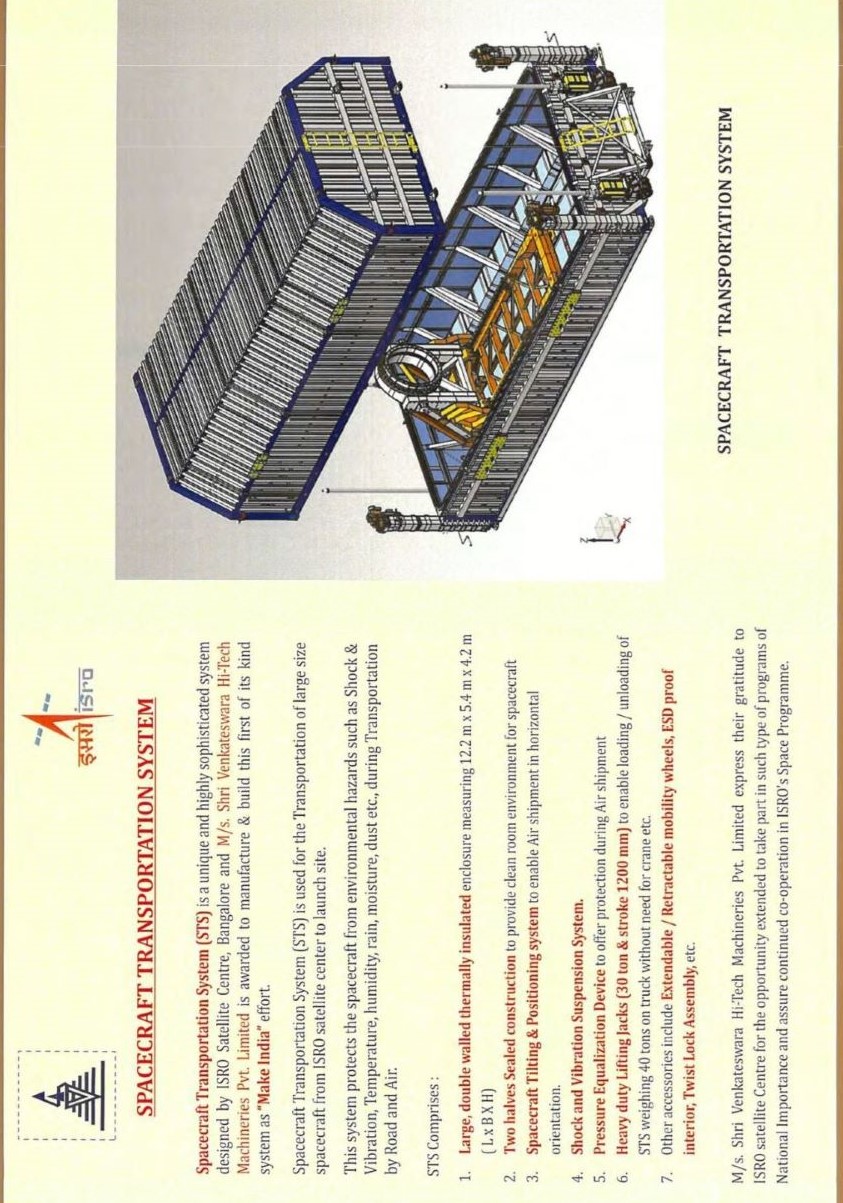

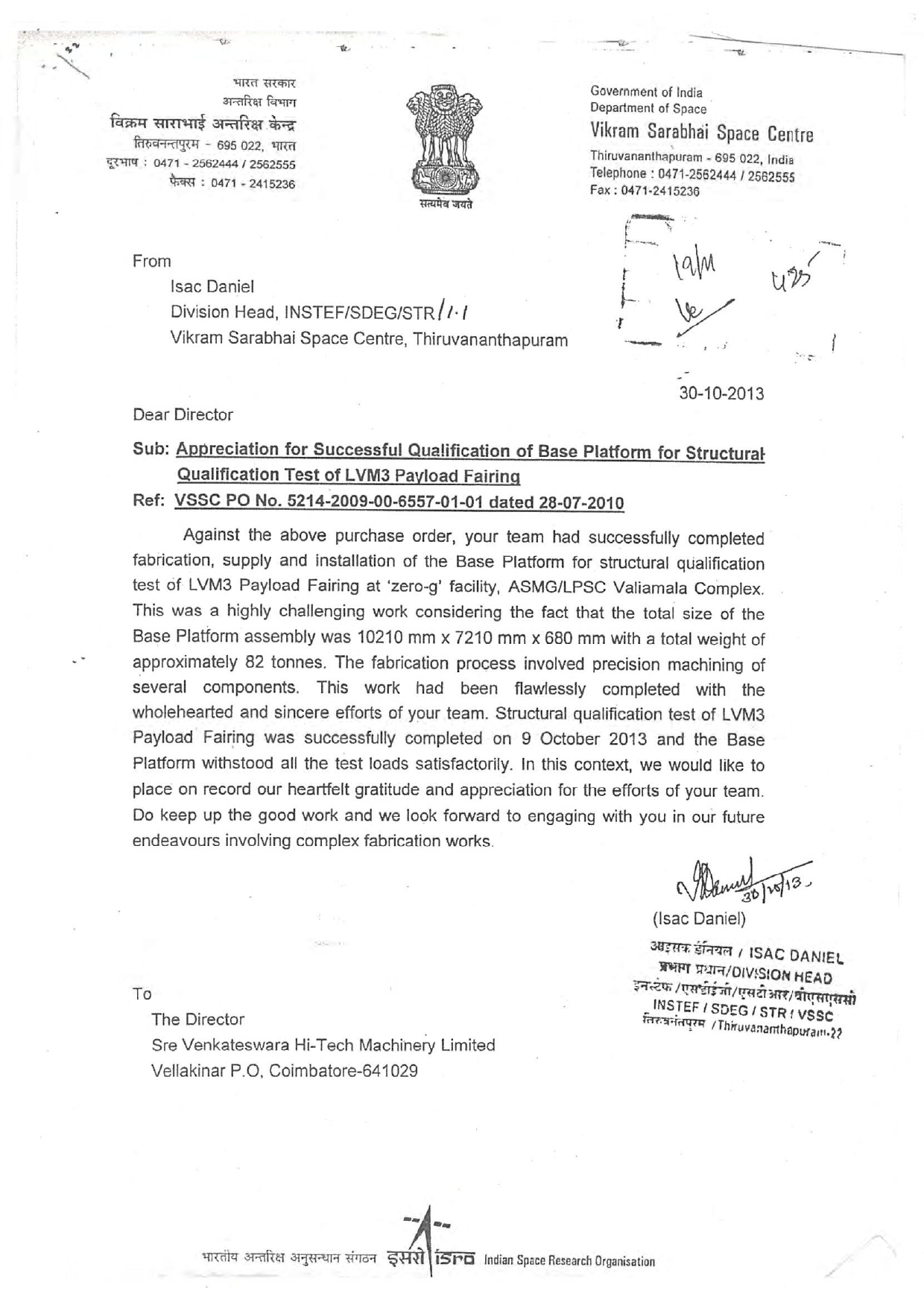

Founded in 1971 by Mechanical Engineer Mr. T. Kaalimuthu, Shri Venkateswara Hi-Tech Machineries began its journey with a pioneering order from the Vikram Sarabhai Space Centre. Over the decades, we have evolved into a Leader in Precision Engineering and Heavy Fabrication, supporting landmark missions such as PSLV, GSLV, Chandrayaan, and Gaganyaan. Our Expertise spans Critical Machining, Heavy Fabrication, Reverse Engineering, and the Delivery of Custom-Built Components to various Engineering Industries

50+

Years of Excellence

1000+

Precision Projects Delivered

50+

Prestigious Clients